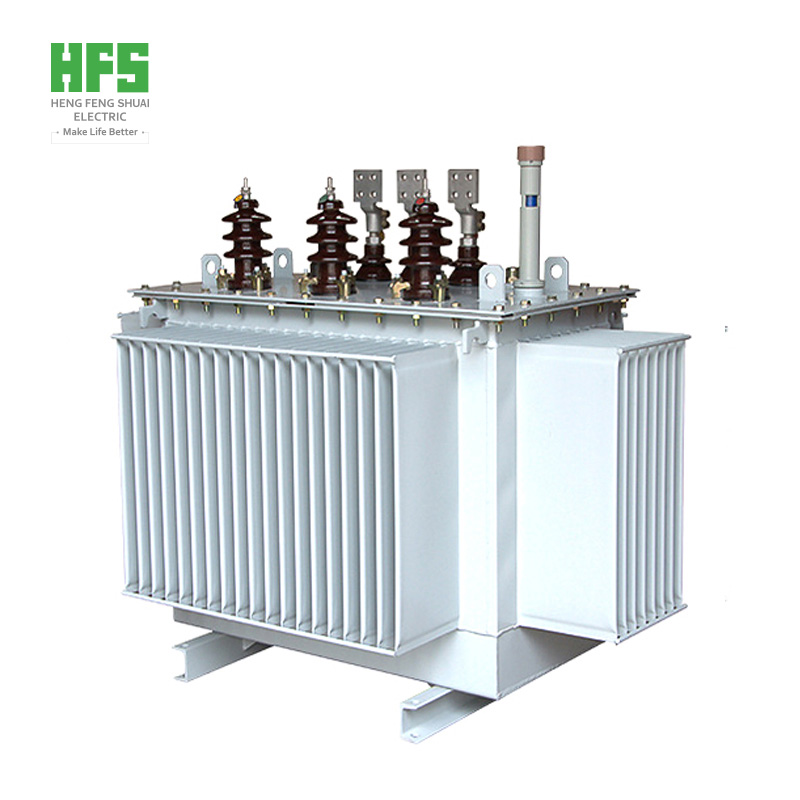

Amorphous alloy oil immersed transformers have the advantages of low loss, good flame retardancy, strong ability to bear short circuit faults, small size, low noise, good lightning impact resistance, and well distributed temperature. As distribution transformers, they can be widely used in the renovation of power supply systems, as well as multi-layer buildings, airports, subway stations, seaports, and subway stations A wide variety of places with special requirements.

Amorphous alloy oil immersed transformer is mainly composed of transformer coil, transformer winding, transformer insulation layer, transformer conductor, transformer refrigeration equipment and temperature measurement equipment. The coil of the distribution transformer is wound on a high-precision winding machine. The low-voltage winding is of foil coil inductance structure. Natural ventilation air pipes are reserved for large volume transformers. After the coil inductance is carried out, vacuum dryers are carried out. The whole process of pouring and drying is strictly in accordance with the processing standards to complete the actual operation, so that there are no bubbles and cavities in the coil. The transformer commodities can achieve the actual effect of high-quality operation.

Transformer core:

The distribution transformer core of this series of products tends to be hot rolled ferrite core when purchasing high-quality and high magnetic conductivity crystals, and uses excellent ferrite core cutting lines, step laminations at 45 ° full oblique joints, core posts adopt advanced technologies such as F level weftless tape binding and yoke non punching machine pulling plate fixing without moving, and the transformer core surface is wrapped with epoxy resin, which reduces the harm of magnetic leakage and reasonably alleviates the spread of equivalent circuits, The noise of transformer core, full load loss and full load current are reduced, which further improves the appearance design quality of distribution transformer.

High voltage winding:

The high-voltage winding adopts the sectional hierarchical type, which greatly reduces the working voltage of the winding solid layer. The epoxy resin with filler is used for vacuum casting forming, which reduces the local discharge of the internal structure of the winding and improves the electrical characteristics of the coil. The solid layer of the distribution transformer winding is made of DMD epoxy resin prepreg cloth to improve the compressive strength. The surface layer of the winding is filled with glass fiber alkali resistant grid cloth, which improves the impact toughness of the coil and the ability of the distribution transformer to resist short circuit faults. The coil will never crack.

Low voltage winding:

The low-voltage winding adopts foil structure, and the coil adopts radial cooling air duct to improve the heat removal capacity. The solid layer of the low-voltage winding of the distribution transformer adopts DMD epoxy resin prepreg, and the top is sealed with epoxy resin. The overall fixed telephone is formed.

HENGFENGSHUAI ELECTRIC, is an electrical enterprise with transmission and distribution industry as its main business, integrating product research and development, manufacturing and trade. Designated suppliers for the world's top 500 enterprises .Its main products include power transformers, medium and low voltage switchgear, distribution panel ,circuit breakers, transmission tower ,Cable and other power distribution equipment .The group has five department: Transformer department, Panel department, power transmission tower department, cable department and electrical engineering department. HENGFENGSHUAI ELECTRIC, has been working hard to provide the best transmission, distribution solutions for users all over the world.【WhatsApp:+86158 5325 2696(Jack) +86158 5326 5269(Alisa)hfs@hengfengshuai.com https://www.hengfengshuai.com 】