With the continuous innovation and evolution of technology, product upgrades in various industries have become the trend. In the power industry, Uzbekistan has taken the lead, targeting the development of power transformers with a global perspective, and has a new plan.

Most of Uzbekistan's power generation units were built during the former Soviet Union period. Currently, many power plants have been in operation for over 30 years, and more than 30% of the units have exceeded their designed lifespan but are still in service. The problems of equipment aging, disrepair, and low efficiency are prominent.

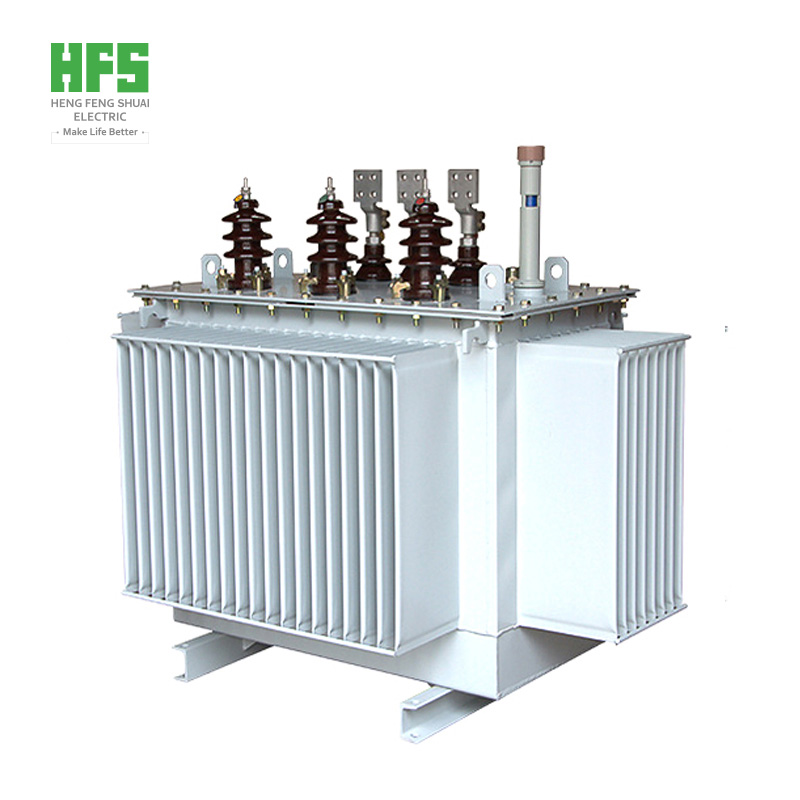

In Uzbekistan's power grid renovation, the most commonly used power transformer equipment is in power plants and substations. Due to the large scale of power grid renovation, there is a high demand for high-quality distribution transformers and related power equipment.

Power transformers are common electrical equipment in the power system, mainly used to transform voltage and current to meet the needs of different power equipment. Power transformers can operate stably for a long time, but with the extension of service time, the quality of the transformer may decrease and its service life will also decrease.

The lifespan of power transformers depends on multiple factors, including materials, manufacturing processes, operating environment, etc. Below, Jack from Hengfengshuai Electric will explain from the following aspects.

1. Materials

In power transformers, the iron core and winding are key materials and components. The iron core is the main structural component of a power transformer, and its quality and performance directly affect the performance of the power transformer. At present, the main iron cores used in power transformers are three iron deficiency and five iron deficiency. Among them, three iron deficiency is widely used in power transformers due to its advantages of low cost, low magnetic loss, and low iron loss. Windings are components that achieve electromagnetic induction, and their materials are conductive materials. The quality of conductive materials directly affects the service life of power transformers. In power transformers, copper or aluminum wire windings are generally used. Copper wire winding is widely used due to its high conductivity and high mechanical strength.

2. Manufacturing process

The production process of power transformers directly affects the service life and performance of transformers. The manufacturing process of power transformers is mainly divided into three steps: winding copper wires, manufacturing iron cores, and assembly. When producing windings, attention should be paid to insulation, transition, and other issues of the windings, otherwise overheating or equipment short circuits may cause serious damage to the transformer. The manufacturing quality of iron cores directly affects the performance of power transformers. During the manufacturing process of iron cores, attention should be paid to issues such as material quality, splicing methods, and core gaps to achieve better performance.

3. Operating environment

The working environment of power transformers can also affect their service life. In the operating environment of power transformers, attention should be paid to issues such as temperature, humidity, and the distance between incoming and outgoing poles. During the use of transformers, do not leave them under heavy load or overload for a long time, as this can also lead to transformer burnout or shortened service life.