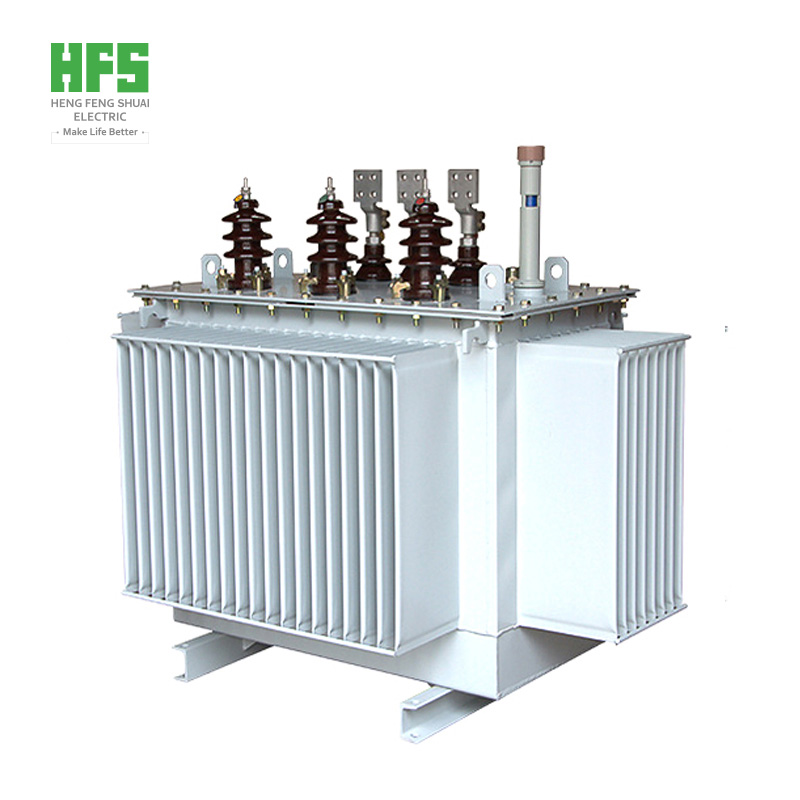

3、 Daily maintenance of 10kV power transformer

(1) Problems such as oil leakage, high or low oil level, abnormal temperature, abnormal sound and abnormal cooling system often occur in the operation of power transformer. Try to find out the causes, correct them and make records.

(2) When the load of the power transformer exceeds the allowable normal overload value, the load of the transformer shall be reduced as required to prevent safety accidents

(3) In case of the following phenomena, the power transformer shall be cut off immediately for maintenance: the internal sound of the power transformer is loud and there is discharge sound; Abnormal temperature and rising phenomenon; Fuel injection of oil conservator or safety airway; The oil level drops to the indication limit of the oil level gauge; The oil color changes too fast; The porcelain bottle is seriously damaged and discharged.

(4) When it is found that the oil temperature of the power transformer is high and the oil level corresponding to the oil temperature is significantly reduced, oil shall be added immediately. When refueling, the regulations shall be observed. If the oil level drops rapidly due to a large amount of oil leakage, the gas protection shall be changed to only act on the signal, and the measures to plug the oil leakage must be taken quickly, and refueling shall be carried out immediately. When the oil level of the transformer rises gradually due to the temperature rise, if the oil level at the highest temperature may be higher than the oil level indicator, the oil shall be drained to reduce the oil level to an appropriate level to avoid oil overflow.

(5) For routine maintenance of dry-type transformer, if power can be cut off, check whether the fasteners are loose and wipe the dust on them. Large and medium-sized maintenance mainly involves measuring insulation resistance, such as high and low voltage to ground resistance.

4、 Treatment of common problems of 10kV power transformer, treatment of oil tank sand hole or weld leakage

(1) The sand hole is small and the oil leakage is small, which can be plugged during operation. Clean the oil leakage part first, then block the oil leakage hole with soap, and apply LD-1 quick acting leakage sealing sealant.

(2) The oil leakage of the weld seam is small. First, clean the paint skin and oxide layer at the oil leakage part to expose the natural color of the box, then scrub it with alcohol and apply sealant. If the leakage part is smooth, it can be roughened on the surface to enhance the adhesion of the sealant.

(3) The oil leakage is large, and the transformer needs to be transported back to the manufacturer for treatment. It is recommended to use carbon dioxide shielded welding or automatic arc welding. After welding, pressure leakage test shall be conducted (generally, 15kpa above 315KVA and 20KPa below 250kVA), and paint shall be applied after it is solved.

For more information, please pay attention to Qingdao hengfengshuai electric. Our factory focuses on the production and manufacturing of American box type substation, which has been sold to the American market in 2018.

American box transformer, American transformer,

pad mounted transformer customized production. Thirty years of production experience in the global power market..

Hengfengshuai Electric will provide you with the best American box transformer product solution. Hengfengshuai electric provides you with the best electrical product solutions. 【WhatsApp:+86158 5325 2696(Jack) +86158 5326 5269(Alisa)hfs@hengfengshuai.com https://www.hengfengshuai.com 】