Product advantages

Leading technology

- Low pressure copper foil winding and high pressure copper tape winding technology, improve lightning resistance

- Small magnetic leakage, high mechanical strength, strong short circuit resistance

- Strong heat dissipation, low temperature rise, can run 120% of the rated load

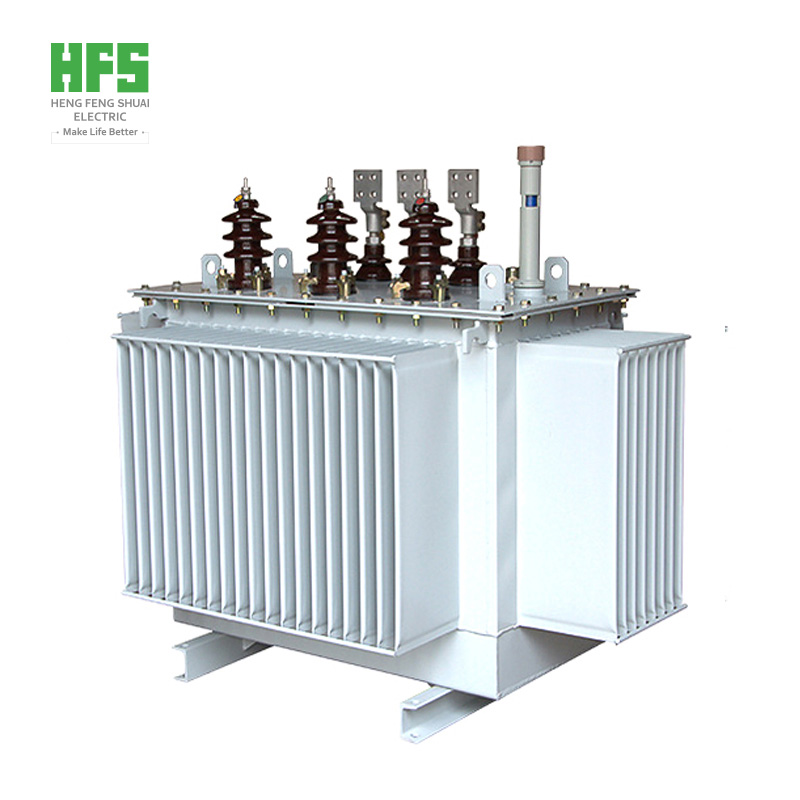

The shell

- Mitsubishi laser cutting machine and CNC punching, reducing, folding and other equipment to ensure the accuracy of processing

- ABB robot automatic welding, laser detection, to avoid leakage, qualified rate of 99.99998%

- Electrostatic spray treatment, 50 years of paint (coating corrosion resistance within 100h, hardness ≥0.4)

- Fully sealed structure, maintenance-free and maintenance-free, normal operation life of more than 50 years

The iron core

- Iron core assembled with high quality amorphous alloy silicon steel sheet

- Minimize loss level, no-load current and noise by controlling the cutting and stacking process of silicon steel sheet

- The iron core is specially reinforced to ensure the transformer structure is firm during normal operation and transportation

Winding

- Low voltage winding is made of high quality copper foil, excellent insulation resistance

- The high voltage windings are usually made of insulated copper wire, using the patented technology of Hengfengyou Electric

- Very good resistance to radial stress caused by short circuit

High quality material

- Sinowisco produces amorphous alloy silicon steel sheet

- High quality anaerobic copper from China

- CNPC (Kunlun Petroleum) High quality transformer oil (25# 40#)

Other instructions

- The low-voltage outgoing terminal is tinned copper bar

- The high-voltage outlet terminals are ring tinned bolts

- Default no-load voltage regulation (on-load voltage regulation can be customized)

Product parameters

Product parameters

| 额定容量Capacity |

额定电压及分接范围Rated voltage&Off-load tapping |

联结组标号

Vector

GroupSymbol |

空载损耗

NO-load

loss(W) |

负载损耗

Load loss(W) |

空载电流

NO-load current(%) |

短路阻抗Short

circuit impedance(%) |

高压

H.V(kv) |

高压分接范围

High pressure

Tap range(%) |

低压

L.V(kv) |

| 30kva |

20 |

±5%

±2x2.5% |

0.4

0.69 |

Dyn11

Yyn0 |

100 |

630/600 |

1.5 |

4 |

| 50kva |

130 |

910/870 |

1.3 |

4 |

| 63kva |

150 |

1090/1040 |

1.2 |

4 |

| 80kva |

180 |

1310/1250 |

1.2 |

4 |

| 100kva |

200 |

1580/1500 |

1.1 |

4 |

| 125kva |

240 |

1890/1800 |

1.1 |

4 |

| 160kva |

280 |

2310/2200 |

1 |

4 |

| 200kva |

340 |

2730/2600 |

1 |

4 |

| 250kva |

400 |

3200/3050 |

0.9 |

4 |

| 315kva |

480 |

3830/3650 |

0.9 |

4 |

| 400kva |

570 |

4520/4300 |

0.8 |

4 |

| 500kva |

680 |

5410/5150 |

0.8 |

4 |

| 630kva |

810 |

6200 |

0.6 |

4.5 |

| 800kva |

980 |

7500 |

0.6 |

4.5 |

| 1000kva |

1150 |

10300 |

0.6 |

4.5 |

| 1250kva |

1360 |

12000 |

0.5 |

4.5 |

| 1600kva |

1640 |

14500 |

0.5 |

4.5 |

| 2000kva |

1940 |

18300 |

0.4 |

5 |

| 2500kva |

2290 |

21200 |

0.4 |

5 |

Ordering instructions

- Main parameters of transformer (voltage, capacity, loss and other main parameters)

- Transformer operating environment (altitude, temperature, humidity, location, etc.)

- Other customization requirements (coupling groups, colors, oil pillows, etc.)

- The minimum order quantity is 1 sets, worldwide delivery within 7 days

- Normal delivery period of 30 days, worldwide fast delivery