Core structure form of transformer 1 There are two basic structure forms of transformer, one is core structure, the other is shell structure. The iron core of the core transformer, the section of the core column is mostly polygonal, and the windings are mostly concentric. The magnetic circuits of each phase of the core of a three-phase core transformer are interconnected. The core column section of shell type transformer is mostly rectangular, and the windings are mostly staggered. Each phase magnetic circuit of the iron core of three-phase shell type transformer is independent. Due to the difference between the two structural forms, the process equipment of the manufacturer is also different. Because these two types of structures have their own characteristics, it is difficult to distinguish between high and low, so at present, some manufacturers in the world use the central structure, while others use the shell structure. And once a manufacturer adopts one structural form, it is difficult to switch to another. The traditional structure of transformer industry in China is the heart type, so only the heart type instrument is discussed.

2. There are also a variety of structural forms, but in general, they can be summarized into three types: the laminated core made of flat silicon steel sheet is rolled into a coiled core made of long silicon steel sheet; An involute iron core assembled from involute silicon steel sheets. The latter two types are only applicable to small capacity transformers and rarely used in China, so only laminated cores are discussed.

3. The part of the iron core surrounded by the winding is called the core column connecting the core column to form a closed magnetic circuit, which is called the iron yoke. The main magnetic flux generated during core excitation flows in the closed magnetic circuit composed of the core column and the iron yoke.

4. In order to make the section shape of the laminated core as close to the circle as possible, so as to make full use of the materials, it is necessary to use multiple sizes of laminations with very small differences in width to stack the core. In theory, it is better to make the number of lamination widths equal to the radius of the contact circle at the iron core divided by the thickness of the lamination. But this will bring great difficulties to the core manufacturing. Therefore, the number of sheet widths used for each iron core in the project is small. Laminations with the same width are called lamination groups, also called "levels". The number of lamination groups in the half section of the outer circle of the iron core is called the series of the iron core. The diameter of the circumscribed circle of the core is usually called the core diameter. The number of cores increases with the increase of core diameter.

5. In order to dissipate the heat generated by the iron core during operation, the iron core with larger diameter must be equipped with one or more heat dissipation oil channels or air channels in the direction parallel to the lamination surface. For the iron core with larger diameter, another oil duct shall be set in the direction perpendicular to the lamination surface. This iron core is called double frame iron core. At present, with the reduction of unit loss of silicon steel sheet, double frame iron core is rarely used.

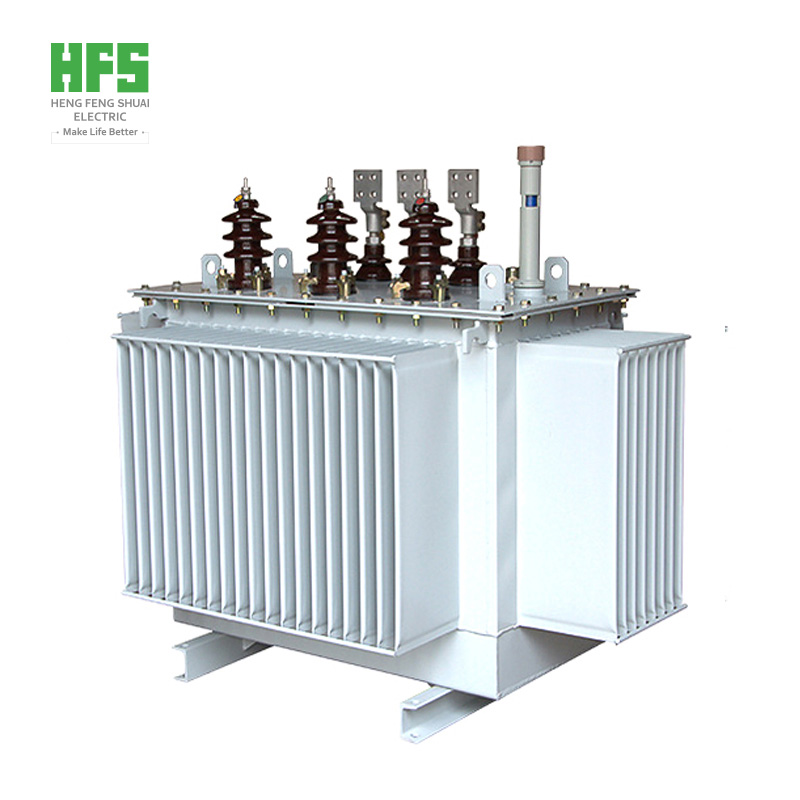

HENGFENGSHUAI ELECTRIC, is an electrical enterprise with transmission and distribution industry as its main business, integrating product research and development, manufacturing and trade. Designated suppliers for the world's top 500 enterprises .Its main products include power transformers, medium and low voltage switchgear, distribution panel ,circuit breakers, transmission tower ,Cable and other power distribution equipment .The group has five department: Transformer department, Panel department, power transmission tower department, cable department and electrical engineering department. HENGFENGSHUAI ELECTRIC, has been working hard to provide the best transmission, distribution solutions for users all over the world.【WhatsApp:+86158 5325 2696(Jack) hfs@hengfengshuai.com https://www.hengfengshuai.com 】