1、 Factors affecting no-load noise

The main reason for the core noise is that the size of silicon steel sheet will change slightly under the action of alternating magnetic field. Since the change period of magnetostriction is half of the power frequency, the vibration of transformer body caused by magnetostriction is based on twice the power frequency, so the vibration of silicon steel sheet is mainly caused by the magnetostriction characteristics of ferromagnetic materials.

The magnitude of magnetostriction is related to the material of silicon steel sheet. The greater the magnetostriction, the greater the noise. When the magnetic field strength is the same, the magnetostriction of silicon steel sheet with good material is also small, so the noise is small. The magnetostriction rate is also related to the magnetic field strength. The stronger the magnetic field, the greater the noise.

The magnetostriction rate is also related to whether the silicon steel sheet surface is painted and annealed, because the coating has adhesion to the silicon steel sheet, which can prevent the silicon steel sheet from deformation. The magnetostriction of silicon steel sheet annealed under the same magnetic field strength is much smaller than that of non annealed silicon steel sheet. This is due to the selection of * * * annealing process, which can reduce the magnetostriction exponentially.

The no-load noise of transformer is not only related to its own material, but also related to the condition of joints.

2、 Other factors affecting no-load noise

(1) Influence of iron core structure. The noise is related to the diameter of the core column and yoke, the height of the core window, the width of the core window, and the quality of the core. The noise can be reduced by 1/3db (a) for every 1t reduction of iron core mass. When the ratio of the core window height to the core diameter decreases by 0.1, the transformer noise will be reduced by 2-3db.

(2) The frequency of no-load noise is based on twice the power frequency. In addition to the fundamental frequency magnetic flux, there is also high-frequency magnetic flux in the iron core, so the no-load noise frequency also has more than two high-frequency frequency waves. When the natural frequency of the iron core oil tank is close to the noise frequency, noise resonance will occur, which will increase the noise. Therefore, the natural frequency of transformer core and oil tank should avoid some high-frequency waves.

(3) In order to prevent core resonance, the natural vibration frequency of the core shall also be considered when designing low noise transformers. When the rated frequency of the transformer is 50 hz, the natural frequency of the core shall avoid the following frequency bands: 75-125 hz, 165-235 hz, 275-325 hz, 375-425 hz. If the natural frequency avoids the resonance frequency band, the iron core will not have resonance.

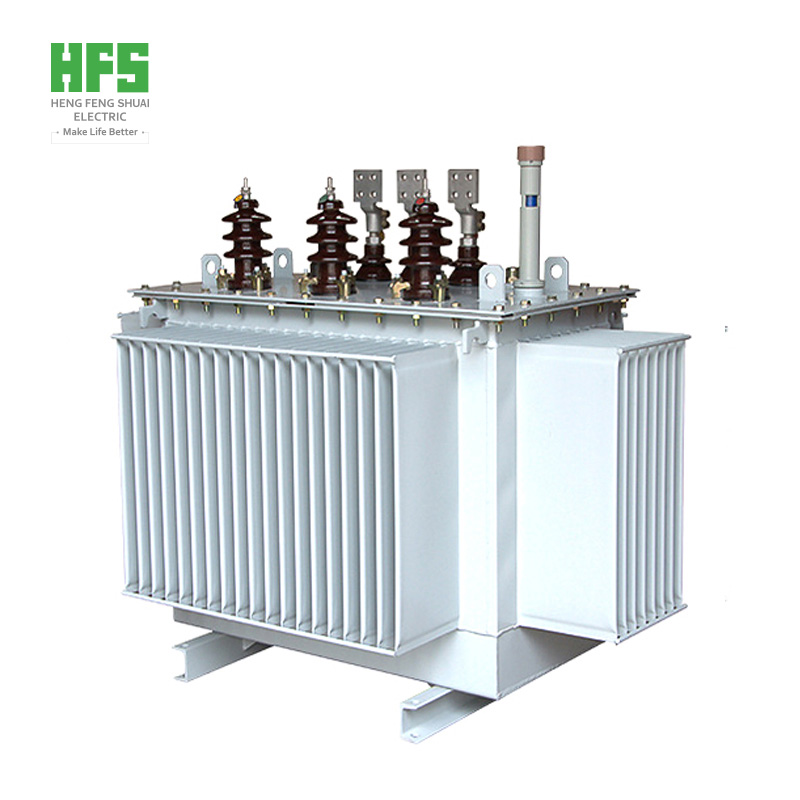

HENGFENGSHUAI ELECTRIC, is an electrical enterprise with transmission and distribution industry as its main business, integrating product research and development, manufacturing and trade. Designated suppliers for the world's top 500 enterprises .Its main products include power transformers, medium and low voltage switchgear, distribution panel ,circuit breakers, transmission tower ,Cable and other power distribution equipment .The group has five department: Transformer department, Panel department, power transmission tower department, cable department and electrical engineering department. HENGFENGSHUAI ELECTRIC, has been working hard to provide the best transmission, distribution solutions for users all over the world.【WhatsApp:+86158 5325 2696(Jack) +86158 5326 5269(Alisa)hfs@hengfengshuai.com https://www.hengfengshuai.com 】