Product advantages

Leading technology

- High pressure copper tape winding technology, improve lightning resistance

- Low voltage copper foil winding technology, high quality A class insulation material insulation

- Small magnetic leakage, high mechanical strength, strong short circuit resistance

- Iron core 45° full oblique joint step laminated structure

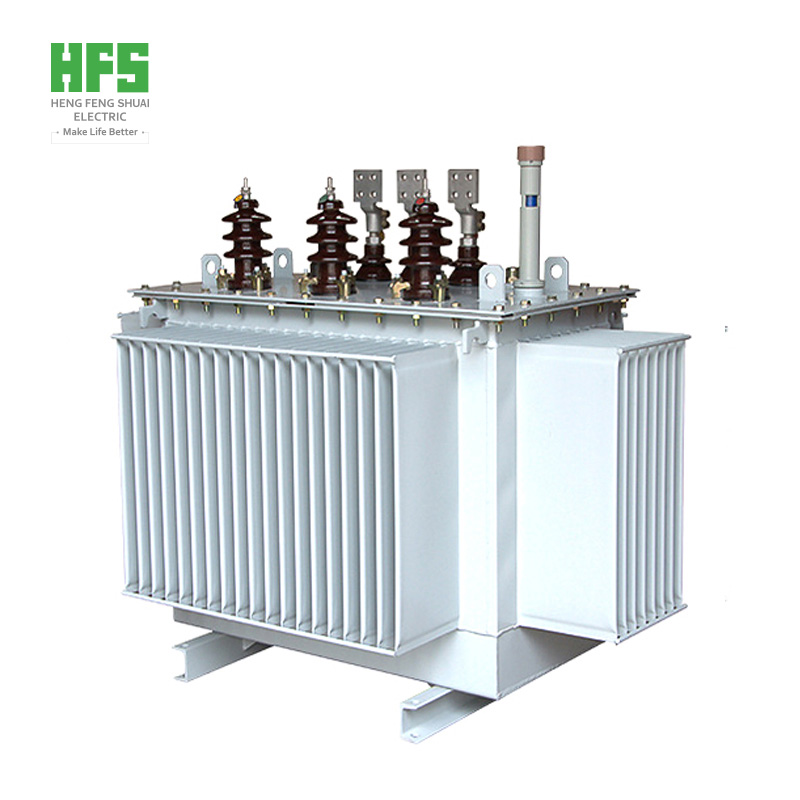

The shell

- Mitsubishi laser cutting machine and CNC punching, reducing, folding and other equipment to ensure the accuracy of processing

- ABB robot automatic welding, laser detection, to avoid leakage, qualified rate of 99.99998%

- Electrostatic spray treatment, 50 years of paint (coating corrosion resistance within 100h, hardness ≥0.4)

- Fully sealed structure, maintenance-free and maintenance-free, normal operation life of more than 30 years

The iron core

- The core material is high quality cold rolled grain oriented silicon steel sheet with mineral oxide insulation (from Baosteel, Wisco, China)

- Minimize loss level, no-load current and noise by controlling the cutting and stacking process of silicon steel sheet

- The iron core is specially reinforced to ensure the transformer structure is firm during normal operation and transportation

winding

- Low voltage winding is made of high quality copper foil, excellent insulation resistance

- The high voltage windings are usually made of insulated copper wire, using the patented technology of Hengfengyou Electric

- Very good resistance to radial stress caused by short circuit

High quality material

- Baosteel, Wisco production of silicon steel sheet

- High quality anaerobic copper from China

- CNPC (Kunlun Petroleum) High quality transformer oil (25#)

Other instructions

- The low-voltage outgoing terminal is tinned copper bar

- The high-voltage outlet terminals are ring tinned bolts

- Default no-load voltage regulator NLTC (OLTC can be customized) tap switch 5 or 7

- Transformers above 630KVA are protected by gas relays

Patent technology

- Thanks to hengfengyou electric "ultra-low loss energy saving power transformer" patent technology, can realize 5% material saving, transformer loss than similar products in the market reduced 10-20%, more energy saving and environmental protection.

Product parameters

Product parameters

Ordering instructions

-

Main parameters of transformer (voltage, capacity, loss and other main parameters)

- Transformer operating environment (altitude, temperature, humidity, location, etc.)

- Other customization requirements (tap switch, color, oil pillow, etc.)

- The minimum order quantity is 1 sets, worldwide delivery within 7 days

- Normal delivery period of 30 days, worldwide fast delivery