Product advantages

> Leading technology

- Standard anti-corrosion and salt spray environmental plan to meet the stringent environmental requirements of the site

- Compact structure, small footprint, easy installation

- Fully enclosed, fully insulated structure, safe and reliable operation

- Easy to operate, maintenance-free, low equipment cost

> Enclosure

- Adopt cold rolled high quality hot dip galvanized sheet

- The surface is treated by electrostatic spray, and the paint can not be taken off for 50 years

- Laser numerical control equipment cutting, drilling, bending, to ensure the processing accuracy

- Product structure is divided into three parts: high voltage chamber, low voltage chamber and transformer

- The cabinet is mainly pre-installed with: lightning arrester, load switch, transformer tap switch, protection fuse, oil level thermometer, oil level gauge, pressure relief valve, amount of oil discharge valve and other accessories

- The low-voltage side is equipped with main circuit breaker, overvoltage protector, and can be designed and installed in complete sets of automatic measurement and intelligent control system

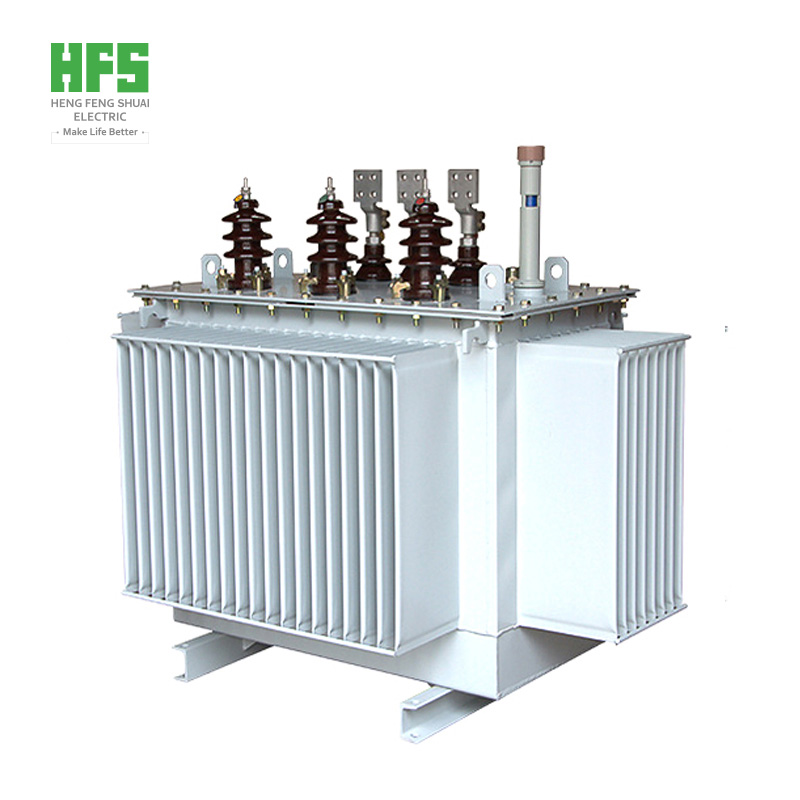

- The transformer is a low loss oil-immersed transformer produced by Hengfeng You Electric

> Functional units

- Fully sealed structure, using the transformer insulating oil as the insulating medium and heat dissipation medium, overall has the advantages of compact structure, good heat dissipation performance

- The high-voltage indoor door should be equipped with electromagnetic lock and live display. When the high-voltage side is live, the high-voltage chamber door cannot be opened. The external door of the box transformer should be equipped with mechanical lock to meet the five requirements of high-pressure products and ensure personal safety

> Components

- Choose high-quality brand components such as Chint, Shanghai People Electric, Changshu Electric, etc

- Schneider, ABB high-quality partners

> Supplementary material

- High quality tin - plated busbar copper bar, with insulation sleeve

- Hanhe cable is selected for secondary wiring

> Processing and assembly

- Assembly workers have been trained for at least 6 months

- Secondary wiring is fully automatic equipment cutting to ensure reliable wiring

- Use power tools to ensure proper torque for bolting reinforcement

- The copper wire bus is NC punched and bent

- All kinds of experimental tests before leaving the factory to ensure normal operation

Product parameters

Product parameters

>Product parameters

-Voltage:0.69kv/33kv 0.69KV/11kv

>Conditions of use

- Altitude: ≦2000m

- Ambient temperature range: -45℃ -- +45℃

- Outdoor wind speed: ≤35m/s

- Relative humidity: daily mean ≤95%, monthly mean ≤90%

- Installation location: Install in the place without fire, explosion risk, serious pollution, chemical corrosion and violent vibration

- If the above normal operating conditions are exceeded, customers can contact our company for customized solutions

- The above is suitable for 50/60Hz photovoltaic power generation system, the rated capacity of the transformer is 500~ 1600KVA

Ordering instructions

When ordering, the customer shall provide the following information:

- Main loop scheme diagram and secondary loop system diagram

- Electrical schematic diagram of auxiliary circuit and wiring terminal layout

- Equipment layout drawing, combination drawing, floor plan drawing

-Brand, model, specification and quantity of main electrical components of the equipment

- Incoming and outgoing line method and cable specifications

- Device surface color

- Other special requirements can be negotiated with the manufacturer