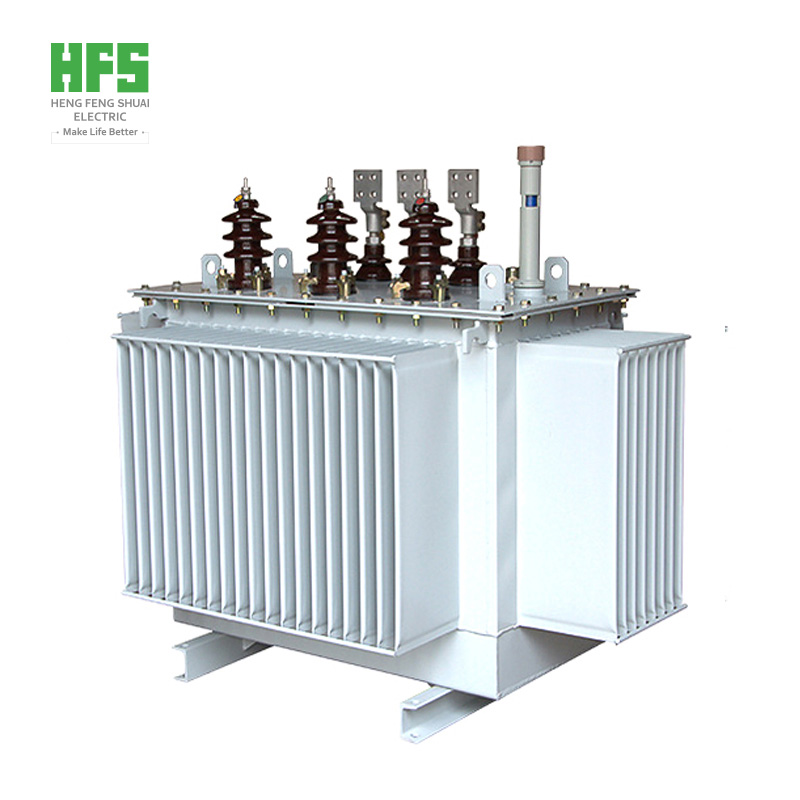

Product advantages

Leading technology

- High pressure copper tape winding technology, flame retardant formula vacuum pouring

- Low pressure copper foil winding technology, thermosetting epoxy prepreg cloth insulation

- High quality iron core 45° full oblique joint step laminated structure

The iron core

- The core is made of high quality cold rolled grain oriented silicon steel sheet insulated by mineral oxide

- Minimize loss level, no-load current and noise by controlling the cutting and stacking process of silicon steel sheet

- Apply class F or CLASS H core paint on the surface of assembled cores to prevent corrosion and rust

Low voltage winding

- The low voltage winding is made of high quality copper foil

- Insulated by thermosetting epoxy preimpregnated cloth

- Winding ends are insulated with thermosetting epoxy preimpregnated cloth

- Excellent insulation resistance

- Very good resistance to radial stress caused by short circuit

- The outgoing terminal of the low-voltage winding is tinned copper bar

- The whole winding is heated in the oven to 140°C and polymerized for 4 hours. It has excellent corrosion resistance of industrial gas

High voltage winding

- Made of insulated copper wire and using the patented technology of Hengfengyou Electric

- For small volume products, the high voltage winding uses a linear voltage gradient from top to bottom

- For products with large capacity, the high voltage winding is made by "tape winding" technology

- The application of these methods makes the electric field between adjacent conductors very low

- Transformer structure is reliable during normal operation and transportation

High quality material

- Baosteel, Wisco silicon steel sheet

- China produces high quality anaerobic copper

- Huntsman Epoxy resin (including flame retardant filler)

Patent technology

- The high voltage coil is molded under high vacuum, and the castable material system adds a unique flame retardant filler, which is a patented technology of Hengfengyou Electric. When the transformer is exposed to flame, it will immediately self-extinguish. With unique and excellent flame retardant characteristics and the ability to adapt to bad working environment.

Product parameters

Product parameters

| 额定容量Capacity |

额定电压及分接范围Rated voltage&Off-load tapping |

联结组标号

Vector

GroupSymbol |

空载损耗

NO-load

loss(W) |

负载损耗

Load loss(W)

F级绝缘 |

空载电流

NO-load current(%) |

短路阻抗Short

circuit impedance(%) |

高压

H.V(kv) |

高压分接范围

High pressure

Tap range(%) |

低压

L.V(kv) |

| 30 |

11 10.5

10 6.6

6.3 6 |

±5%

±2.5% |

0.4

0.69 |

Dyn11

Yyn0 |

150 |

710 |

2 |

4 |

| 50 |

215 |

1000 |

2 |

4 |

| 80 |

295 |

1380 |

1.5 |

4 |

| 100 |

320 |

1570 |

1.5 |

4 |

| 125 |

375 |

1850 |

1.3 |

4 |

| 160 |

430 |

2130 |

1.3 |

4 |

| 200 |

±5%

±2x2.5% |

495 |

2530 |

1.1 |

4 |

| 250 |

575 |

2760 |

1.1 |

4 |

| 315 |

705 |

3470 |

1 |

4 |

| 400 |

785 |

3990 |

1 |

4 |

| 500 |

930 |

4880 |

1 |

4 |

| 630 |

1070 |

5880 |

0.85 |

4 |

| 630 |

1040 |

5960 |

0.85 |

6 |

| 800 |

1215 |

6960 |

0.85 |

6 |

| 1000 |

1415 |

8130 |

0.85 |

6 |

| 1250 |

1670 |

9100 |

0.85 |

6 |

| 1600 |

1960 |

11700 |

0.85 |

6 |

| 2000 |

2440 |

14400 |

0.7 |

6 |

| 2500 |

2880 |

17100 |

0.7 |

6 |

Ordering instructions

- Main parameters of transformer (voltage, capacity, loss and other main parameters)

- Transformer operating environment (altitude, temperature, humidity, location, etc.)

- Other customization requirements (coupling groups, colors, oil pillows, etc.)

- The minimum order quantity is 1 sets, worldwide delivery within 7 days

- Normal delivery period of 30 days, worldwide fast delivery