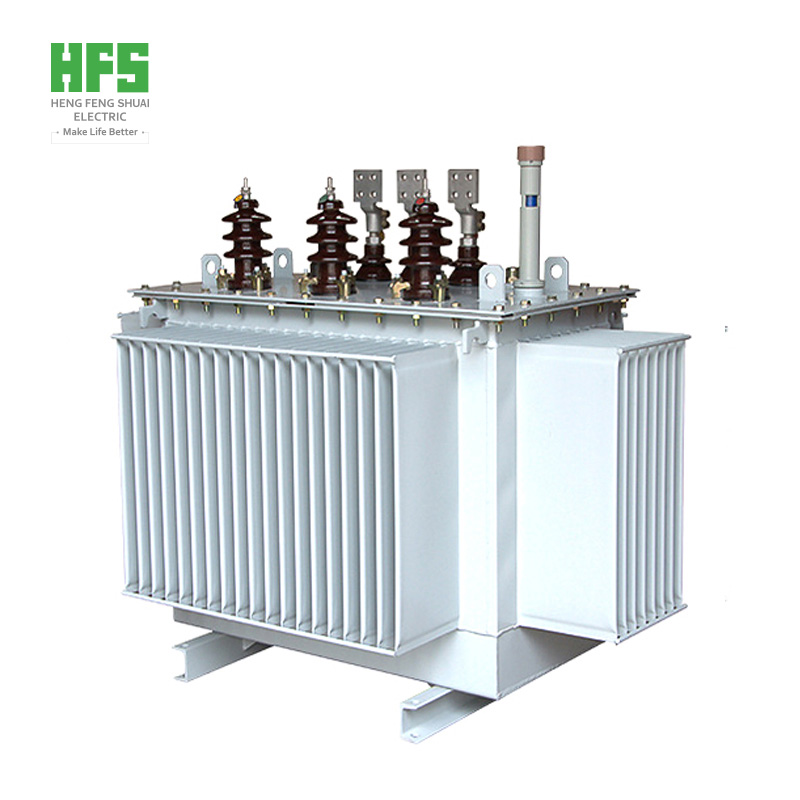

Product advantages

Leading technology

- Standard anti-corrosion and salt spray environment scheme, meet the strict environmental requirements of the site

- High breaking ability, good dynamic thermal stability, advanced structure, arbitrary combination of various scheme units

- A single cabinet can accommodate more loops, high safety protection level (IP30) easy maintenance

Cabinet put oneself in another's position

- The whole use of 8MF type open steel, the two sides of the steel have modules of 20mm and 100mm and 9.2mm mounting holes respectively

There are two kinds of assembly forms, full assembly type structure and part (side frame and beam) welding type structure

- Compartment is divided into functional unit room, bus room and cable room, the function of each room is relatively independent for live maintenance

- Laser CNC equipment cutting, drilling, bending, ensure processing accuracy

- External electrostatic epoxy powder coating, 50 years of paint

- Mold size, hole size and equipment spacing are modular (module E=160mm)

Functional unit (drawer part)

- The module of drawer height is 160mm (divided into 1/2 unit,1 unit,3/2 unit,2 unit,3 unit), and the maximum rated current of unit loop is 400A

- The drawer changes only in height size changes, its width, depth size unchanged, the same functional unit of the drawer with good interchangeability.

- Each MCC cabinet can be fitted with 11 one unit drawers or 22 1/2 unit drawers, of which more than one unit drawer has a multi-function back board

- the plugins of the same specification chip structure with different number of pieces according to the current size.

- The drawer unit is equipped with mechanical interlocking device so that the door panel cannot be opened when the main switch is closed

- The drawer unit has a sufficient number of secondary plug pieces, which can meet the requirements of computer interface and automatic control circuit number of contact points

Busbar system

- Three-phase four-wire system or three-phase five-wire system

- High quality three phase tinned bus copper bar, high mechanical strength, good heat dissipation

- The horizontal bus arrangement makes the device have good dynamic and thermal stability, and can withstand the impact of 80/176kA short-circuit current

Processing and assembly

- Dust-free workshop to ensure insulation

- Assembly workers must be trained for at least 6 months

- Automatic terminal crimping machine for secondary wiring to ensure reliable wiring

- Bolt reinforcement using power tools to ensure proper torque

- The copper busbar is CNC cutting, punching and bending to ensure accuracy

- All kinds of experimental tests before delivery, to ensure the normal operation of equipment

- Welcome customers to visit the factory, provide OEM/ODM protection level

Product parameters

Product parameters

The customer shall provide the following information:

- Main loop scheme diagram, secondary loop system diagram and auxiliary circuit control mode

- Equipment layout and distribution room layout

-Brand and model of main electrical components of the equipment

- In and out mode. If a bus bridge is required to connect devices, data such as bus spacing and ground height should be provided.

- Other special requirements can be negotiated with Hengfengyou Electric

Ordering instructions

Detailed data online inquiry

The customer shall provide the following information:

- Main loop scheme diagram, secondary loop system diagram and auxiliary circuit control mode

- Equipment layout and distribution room layout

-Brand and model of main electrical components of the equipment

- In and out mode. If a bus bridge is required to connect devices, data such as bus spacing and ground height should be provided.

- Other special requirements can be negotiated with Hengfengyou Electric